Strength of

Hokuichi

The fundamental idea behind Hokuichi’s manufacturing is that small improvements lead to big outcomes.

Every day, we ask ourselves how we can become a better factory than yesterday. Every day, we look for room for improvement. However small the room might be, we take it as an opportunity to improve product quality and production efficiency further. We call our systematic approach to improvement as Hokuichi Innovative Production System, or HIPS, which all employees share and practice.

Manufacturing×Quality Control×Management

The production system involves manufacturing, quality control, and management teams to achieve optimal output, for which the teams are committed to optimizing their procedures and workflows.

“Manufacturing system”

(a structure which allows anyone to produce goods exactly as they should and in the most efficient way).

Standard management.“Quality control system”

(a structure which prevents defects from occurring or being passed further along the process).

Predictive and preventative management.“Management system”

(a structure which prevents the generation or retention of any excess).

Shortest possible delivery deadlines, optimal inventory management.Machine

Advanced next generation soldering machine

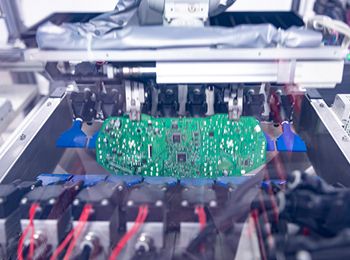

Component Loader Equipped Laser Soldering Machine

No-contact processing keeps printed circuit boards free from any external stress.

Printed circuit boards are laser soldered without being exposed to physical contact during the soldering.

Superior soldering performance is achieved with heating efficiency and a stable supply of solder.

Once the machine is programmed with a laser power level, laser spot diameter, and soldering position, the machine automatically performs required tasks at a high level of quality.

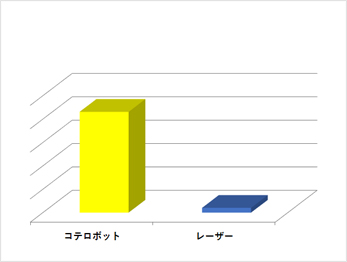

Reduction of Running Cost

No soldering iron tips means no need for parts replacement resulting from wear and tear. Since no solder paste is wasted on solder iron tips, the solder paste volume required for operation is accurately manageable.

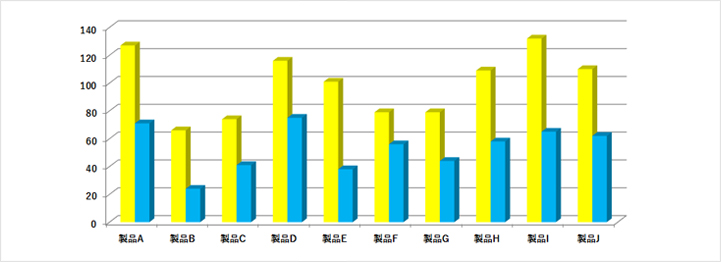

Laser soldering was 30-60% faster than the conventional soldering robot.

Laser soldering improved yield by 90% compared to the conventional soldering robot.

Automatization and Optimization of Operation

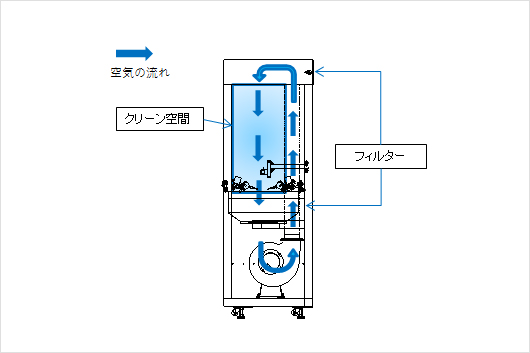

Conveyor system with air blower

Operation Accuracy

Robotic transporting eliminated the operation variation associated with manual work.

Dust proofing products became efficient and effective by widening the mouth of the air blower.

Improved Dust proofing and Dust Collecting

Downward air stream sends contaminants into the dust collector, giving them no chance to stay in the workspace and contaminate products in the process.

Benefits of Going Unmanned

Our clean room tasks, which used to be operated by people who were in clean room gowns wearing goggles, have been replaced by robots. The change improved Hokuichi’s production efficiency and quality.

Conveyor System with Air Blower

Air blow Robot

Air blow Robot

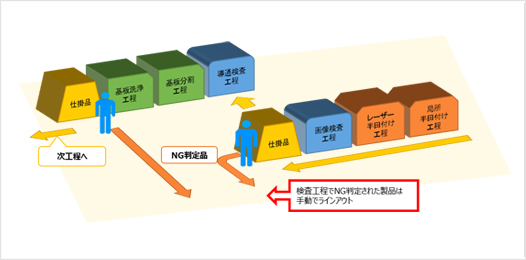

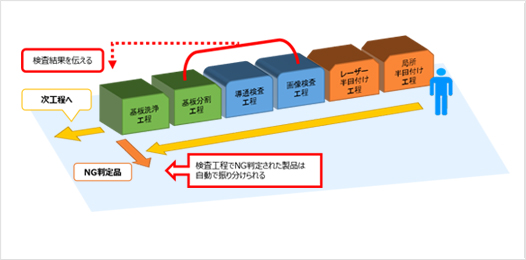

Connected Production Line

Lean Stock

Eliminate idle time on the production lines and aim to have zero WIP products.

Lead-time Reduction

Drastically reduce lead-time by minimizing idle time on production lines.

Space Optimization

Because we have no waiting products in WIP, we do not need to secure storage area for such products. Therefore, our floor space is efficiently utilized.

Optimized Workforce

Redesigning the production lines eliminated the need for movements, such as loading and unloading and transporting. The line operators were reduced from two to one because of the change.

Before

After connecting the lines for optimization

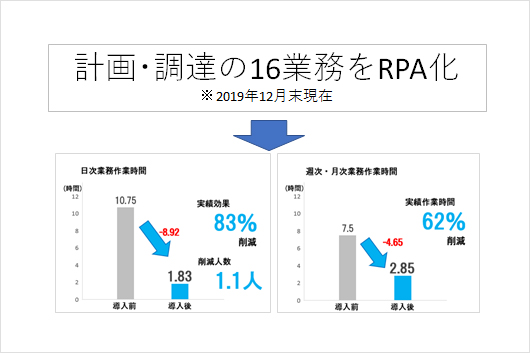

Robotic Process Automation/RPA

Streamline Operations

Hokuichi has incorporated RPA and significantly reduced time taken for multiple tasks by simultaneously processing them.

Improvement in Data Output Accuracy

Hokuichi is happy to utilize RPA because it greatly eliminated the burden of simple repetitive documentation work, including copying, pasting, and other manual tasks.

Abbreviation for Robotic Process Automation, also known as Distal Labor. It is defined as a mechanism to streamline and automate white-collar work by utilizing rule engine, machine learning, artificial intelligence, etc.

RPA is defined as an effective method to streamline and automate office work by utilizing rule engine, machine learning, and artificial intelligence (AI).