FACTORY TOUR

Approximately 1 of every 10 vehicles made in Japan use Hokuichi’s products.

Virtually Explore Hokuichi’s Cutting-edge Production System!

Welcome to Hokuichi’s powerhouse to create outstanding productivity and flexibility, the source of our competitiveness.

A key strength of our company lies in the mounting equipment installed at our site that supports all types of production methods.

Our fully equipped production line will meet almost any request you may have, especially for circuit board mounting.

TOUR 01

For Quality Assurance and the Environment

We are committed to making our production environmentally responsible to secure our continuous growth as a manufacturing company while maintaining the quality our customers expect.

Quality Assurance

Dust Prevention

Uniforms

We use anti-dust uniforms designed to prevent the release of fibers, dust, and other debris to ensure a clean factory environment. The uniforms also comply with the International Electrotechnical Commission and eliminate static electricity at a high level. Even administrative staff, who rarely visit the factory, wear the same uniform to practice strict discipline for a clean production environment.

Clean-wear Suit

When entering the manufacturing area, wearing an anti-dust clean-wear suit over the uniform is required. A hat specifically designed to cover all hair is also worn.

Shoe Sole Cleaner

When entering the production area, employees change into special shoes and clean the soles of their shoes in a shoe sole cleaner with a brush and liquid detergent.

Air Shower

Employees take a 15-second air shower to thoroughly blow off the fine dust and hair on the surface of their clothes.

Anti-Static Measures

Any static electricity accumulated in the body is detected and discharged using a static electricity detector.

Moisture Control

The humidity is always kept above 50% to prevent any static electricity generated due to dryness in the factory. When humidity drops below 50%, a pure water mist automatically sprays.

Environmental Initiatives

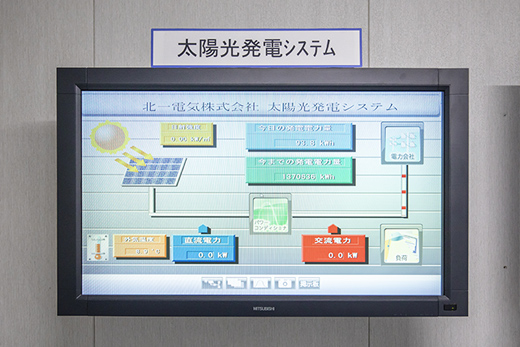

Solar Power Generation System

Leveraging the size and location of the factory, we installed a solar power generation system using the entire roof of the factory starting in 2015. By adopting solar power generation, which emits less carbon dioxide, a cause of global warming, we strive for environmentally responsible corporate activities.

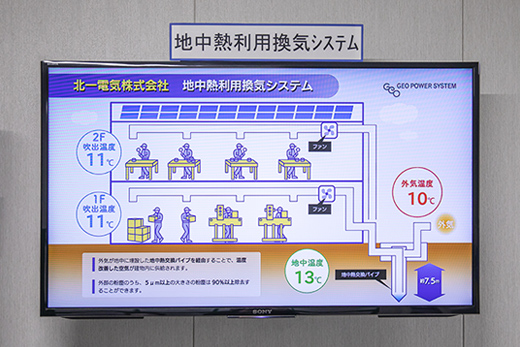

Geothermal Ventilation System

A ventilation system utilizing geothermal heat, stabilized at about 13 degrees Celsius throughout the year, has been installed. Heat exchange utilizing the temperature difference between the geothermal heat and the outside air provides cool air in summer and warm air in winter, resulting in energy savings and reduced heating and cooling costs.

Other Initiatives for the Environment

All metal residue emitted during the manufacturing process is reclaimed by recycling companies to eliminate industrial waste. We have also switched to LED lighting in the company to save electricity.

Design

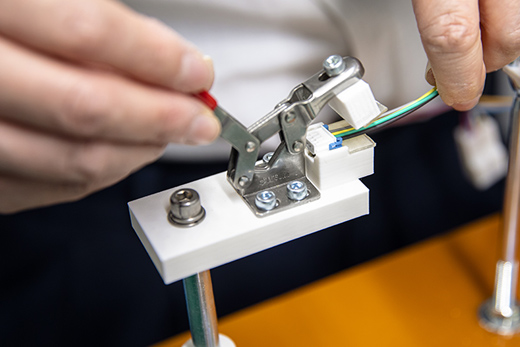

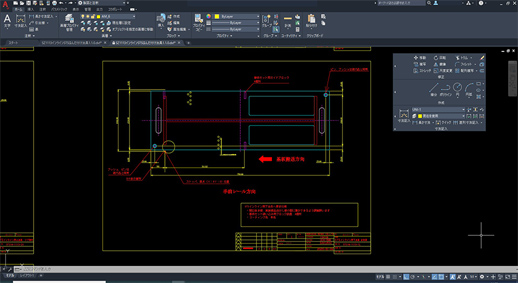

Jig Design

When designing jigs to support components and tools, we devise shapes that are easy for workers to handle and make it easy to detect any mistakes. The improved workability prevents defects, leading to quality assurance.

Process Design

Our customers usually supply production processes; however, in cases where higher quality and lower cost could be achieved, we can design and propose new processes.