What

We Do

Reliable Supplier of High-Quality Products at Competitive Prices Supporter of Innovation in Automobile Technology

Our core products are printed circuit boards, wire harnesses, and in-vehicle electronic components. As

automobile

technology itself has been rapidly evolving, we have responded to the changes in the industry by

introducing the latestbr

equipment and enhancing our technology. In addition, by automating our production lines and

strengthening our inspection

system, we are able to provide higher quality products faster at competitive prices.

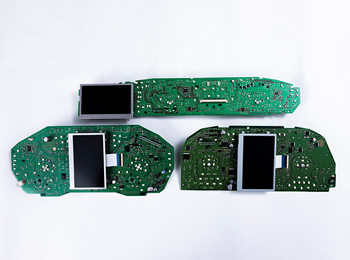

Printed Circuit Boards

We produce about 1.2 million printed circuit boards for speedometers annually to meet our customers’ specifications. We manufacture the products and develop our own processes to provide cost-effective solutions for our customers. Furthermore, we always strive to improve through collaborative development with device manufacturers for increased productivity.

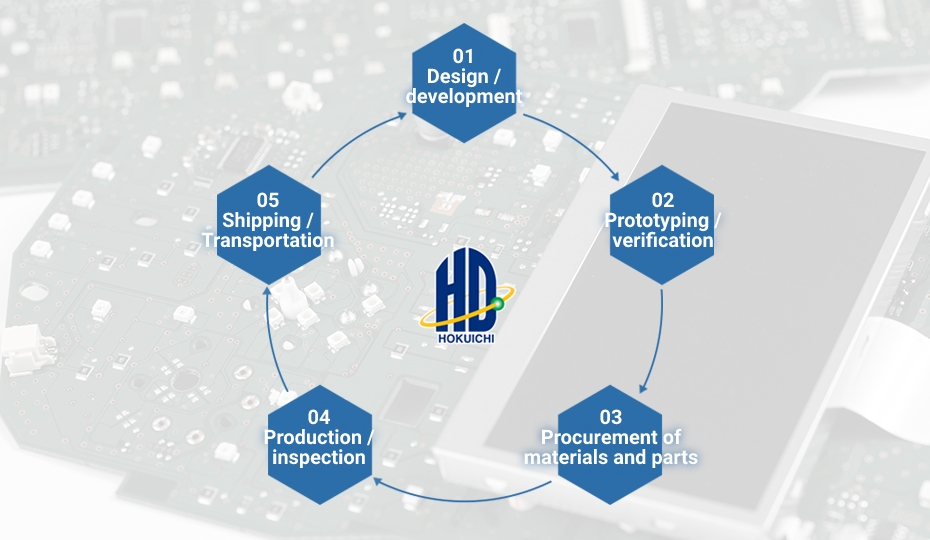

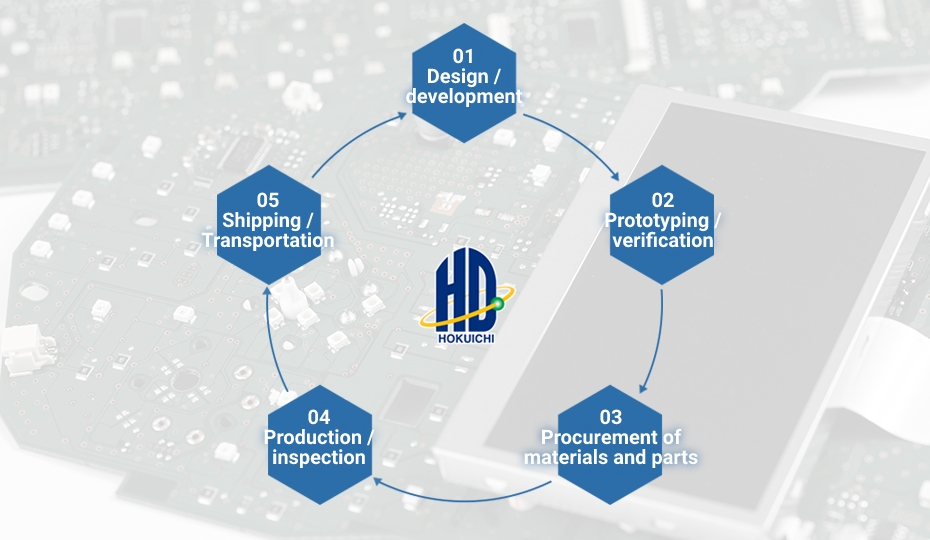

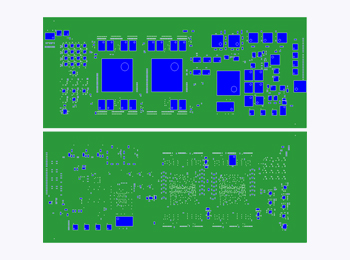

Our One-stop Integrated Service Enables High-Quality and Efficiency.

Our integrated service provides everything you need from production planning, parts procurement, manufacturing, assembly, and inspection, to packaging and shipping. Automated production facilities featuring the most advanced equipment and enhanced inspection systems ensure high-quality, high-efficiency operations.

Our Main Products

Printed Circuit Boards for Indicators

Printed Circuit Boards for Imaging Devices

Problems Acquiring Multiple Items? Looking for a Small Lot? Under Time Pressure?

Our Completely In-house Production Is the Answer.

Our printed circuit board production is completed 100% internally, without outsourcing to third

parties or overseas sites.

This enhances our advantage of mobility and responsiveness, allowing us to flexibly meet your

request for multiple items, small lots, and quick delivery.

Facilities

Chip Mounter (FUJI CORPORATION)

Laser Solder Soldering Equipment

Inline Printed Circuit Board Transport Equipment (Printed Circuit Board Air Blow System)

On-site 3D Inspection Apparatus and X-ray Inspection Equipment Ensure High-quality Ultra-small-scale Components

We are fully equipped with a three-dimensional inspection apparatus for ultra-small-scale components and X-ray inspection equipment to examine parts soldered under a printed circuit board. Since companies with X-ray inspection equipment are relatively rare, we can also handle requests for inspection-only services.

Facilities

3D Solder Inspection Apparatus

3D Solder Appearance Inspection Apparatus

3D Solder Appearance Inspection Apparatus

Our Facilities

You can see this table by scrolling horizontally

| Type | Unit | Remarks |

|---|---|---|

| Surface Mounting Lines | 4 lines | Maximum Work Size: 460510 mm Minimum Supported Component: 0201 Chip Maximum Opening: 74 mm, Maximum Height: 38.1 mm Lead-free reflow system on all lines Automated Solder Appearance Inspection Apparatus: 0603 Chip supported (Installed inline) |

| 3D X-ray Hybrid Inspection Apparatus | 1 unit | X-ray Inspection, 0603 Chip supported |

| Nitrogen Gas Supply System | 2 units | CE: 1 unit, PSA: 1 unit |

Chip Mounter (YAMAHA)

Selective Soldering System

Printed Circuit Board Separator

Wire Harness

With an annual production of 7 million units, the national automakers have adopted our wire harnesses in a wide range of models for exterior lighting fixtures, such as headlights, taillights, and brake lights. In addition to our manufacturing facilities, we also have manufacturing bases overseas in collaboration with our partner companies. We, therefore, offer the most suitable production solutions to meet your volume and cost requirements.

Our Domestic and Overseas Production Network Ensures the Best Possible Prices

In addition to our domestic production site, we have bases in China and Vietnam in collaboration with our partner companies. This allows us to select the most efficient production sites to match your needs flexibly. For example, we can offer overseas production for a large-lot order on a tight budget, or domestic production for a small-lot order requiring complex processes.

Wire Harness Products

For Headlights

For Rear Combination Lamps

For LID Lamps

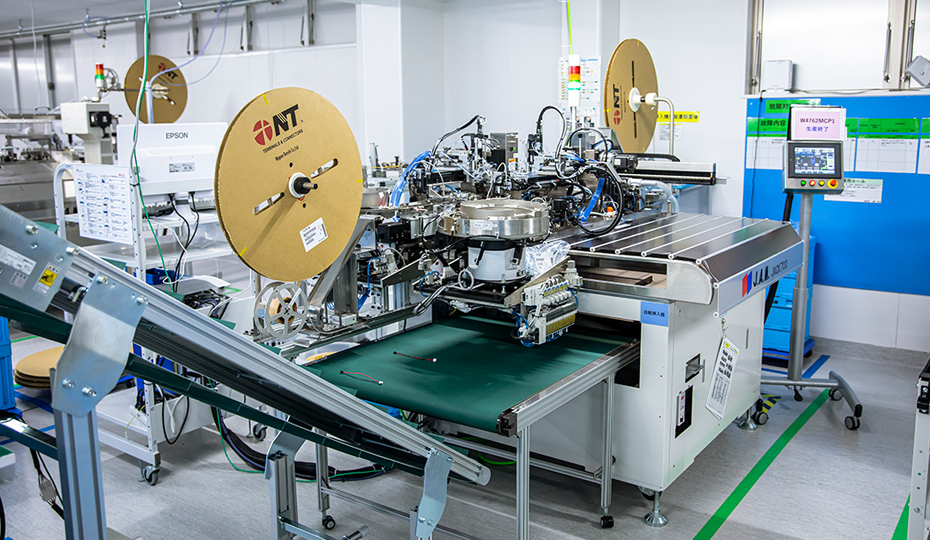

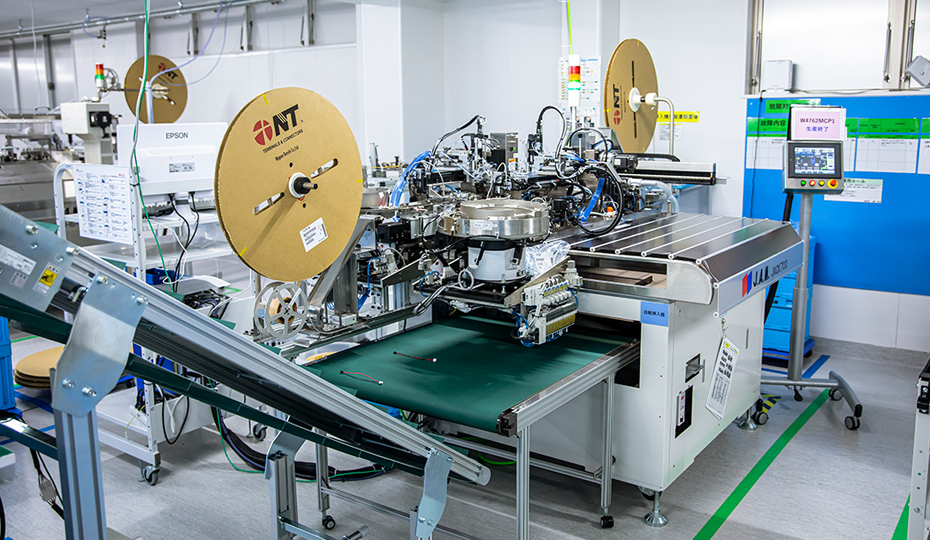

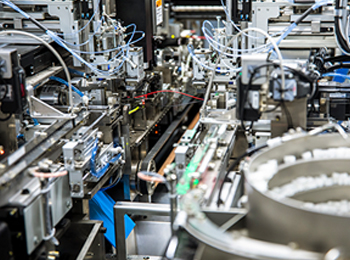

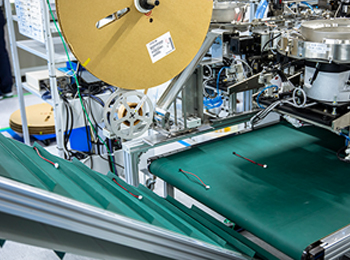

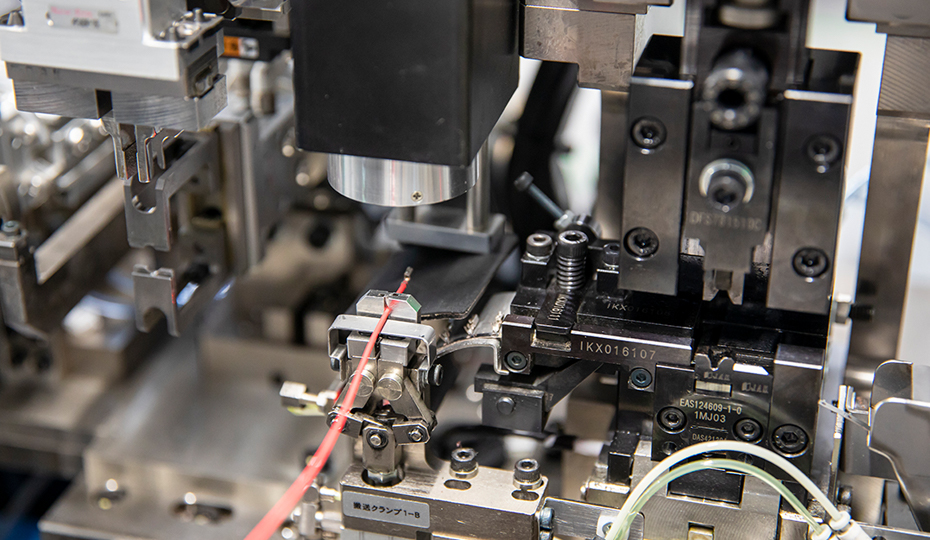

Proactively Shifting to Automation for Higher Efficiency and Quality

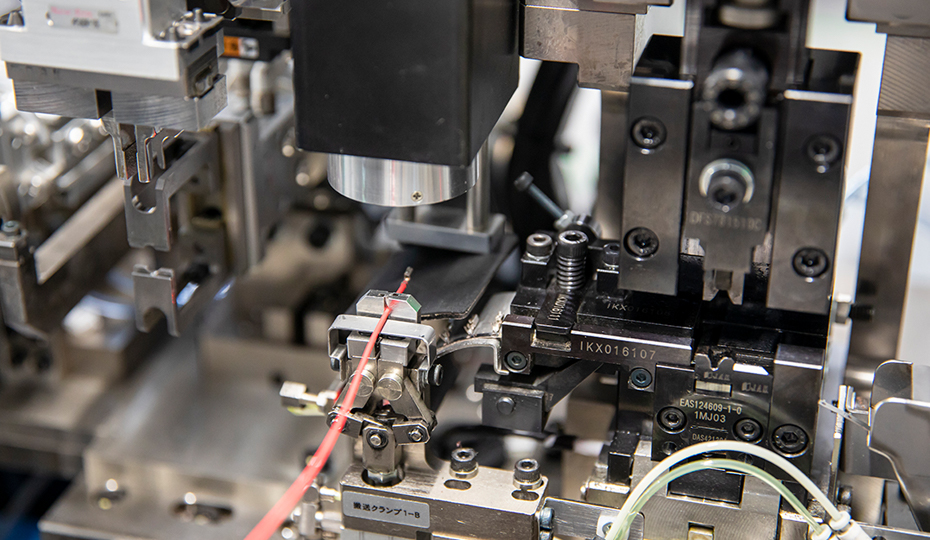

We have successfully implemented the latest equipment, which has always been considered difficult even among industry insiders; Hokuichi started shifting to automated production early on. We have successfully implemented the latest equipment which automatically completes the processes from cutting wires and crimping terminals, to inserting the wire into a connector.

Facilities

Fully Automatic Terminal Insertion Machine, at Inserting View

Transport Conveyor

Wire Joint Taping Machine

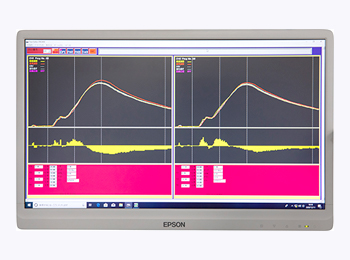

High-spec Inspection Apparatus Promotes Higher Reliability and Safer Production

Our production lines are equipped with a crimp force monitor (a pressure monitoring device) to monitor ordinal crimping of terminals and a high-speed camera to check for abnormal deformation of products. We were among the first in the industry to introduce high-speed cameras on the production floor, contributing to the advancement of product quality.

Facilities

Crimp Force Monitor (CFM)

Crimp Vision Monitor (CVM)

Our Facilities

You can see this table by scrolling horizontally

| Type | Unit | Remarks |

|---|---|---|

| Automatic Wire Cutting and Crimping Machine | 3 | Fully Automatic Terminal Crimping Machine (Both Ends) Fully Automatic Terminal Insertion Machine (Both-end Crimp Insertion) Fully Automatic Terminal Crimping Machine (Both-end Crimping/ One-end Crimp Insertion) |

| Semi-automatic Wire Crimping Machine | 2 | Semi-automatic Terminal Insertion Machine |

| Inspection Apparatus | 6 | Bulb Lighting Electric Conductivity Inspection Machine Wire Harness Checker, WSP Series |

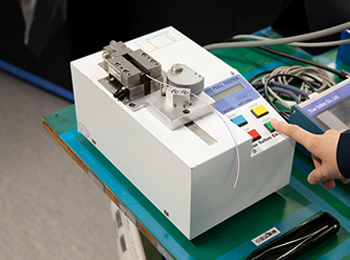

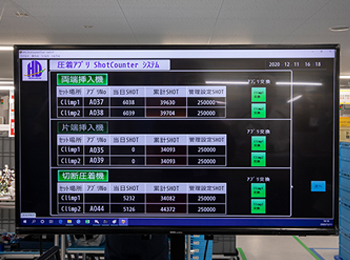

| Others | - | Pneumatic Crimping Tools, Joint Taping Machines, Shot Counters, Electric Strippers, Simple Terminal Crimp Cross-section Monitors, Automatic Tensile Testers, Crimp Shot Counter Systems, Current-Checker Shot Counter Systems |

| Number of applicators owned | 185 | We meet the diverse needs of our customers by owning a large number of applicators, mainly for in-vehicle use. |

Simple Terminal Crimp Cross-section Monitors

Automatic Tensile Testers

Crimp Shot Counter Systems